Time:2019-11-08

Item | Property | Value | Unit | Test Method |

Physical | Density | 1.2 | g/cm3 | ISO 1183 |

Haze | >90 | % | ASTM D1003 | |

Light Transmission | >88 | % | ASTM D1003 | |

Mechanical | Tensile Strength | 60 | MPa | ISO 527 |

Elongation | >100 | % | ISO 527 | |

Bend Strength | 91 | MPa | ISO 178 | |

Tensile Modulus | 2400 | MPa | ISO 178 | |

Surface tension | ≥34 | Dyn/cm | Test fluid | |

Electrical | Dielectric Constant | 3 | - | IEC60250 |

Resistant Puncture Voltage | 30 | KV/mm | IEC 60243 | |

Surface resistivity | 1.00E+16 | Ω/square | IEC 60093 | |

Volume resistivity | 1.00E+17 | Ω-cm | IEC 60093 | |

Thermal | Coefficient of Thermal Expansion | 5.8 | ×10-5/℃ | ISO 11359 |

Thermal Conductivity Rate | 0.2 | W/(m*K) | ASTM D5470 | |

Thermal Shrinkage(150℃) | 0.5~0.7 | % | ASTM D1204 | |

Tg | 152 | ℃ | ISO306 | |

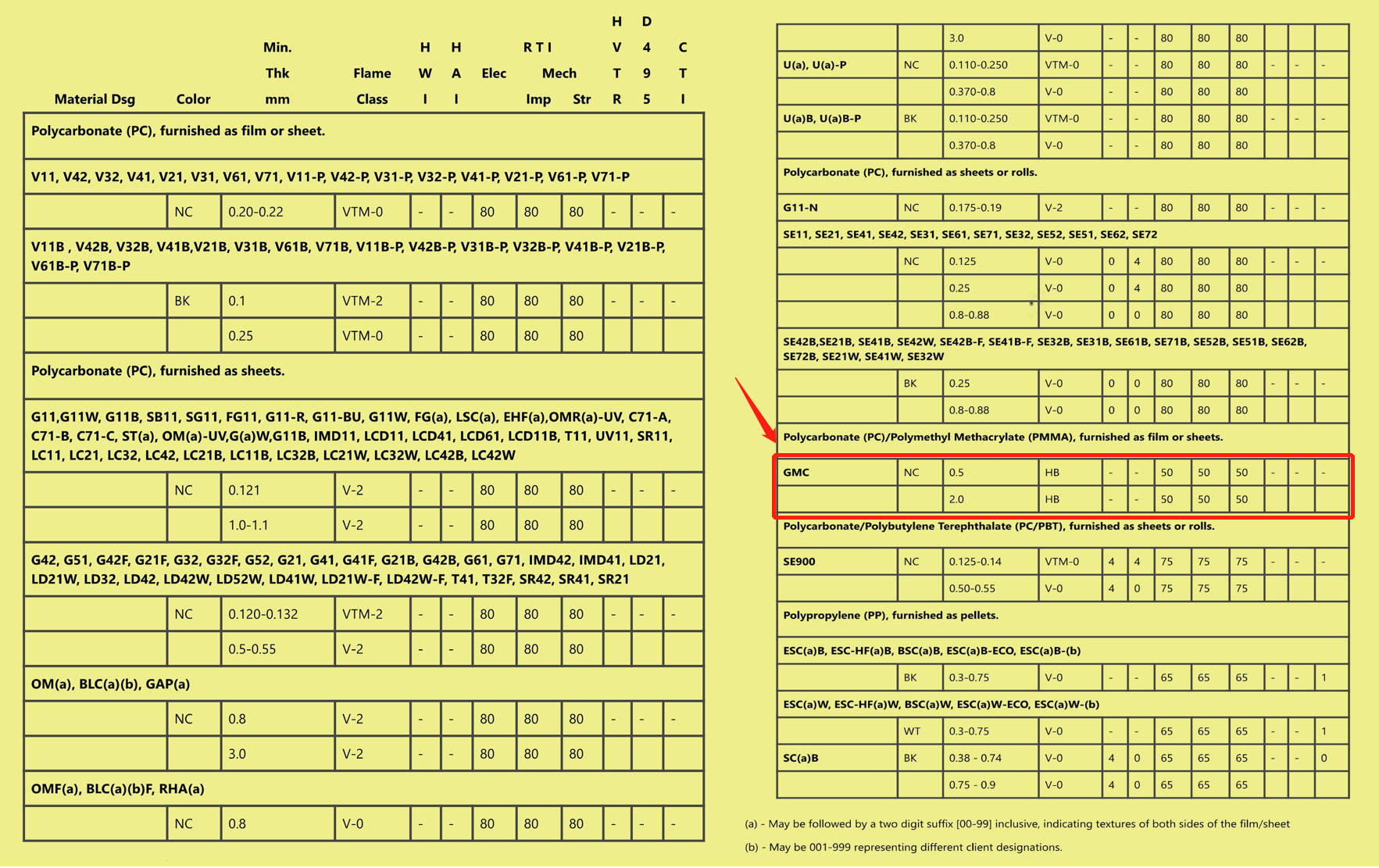

Flammability | Grade of resistant flame | V-2/VTM-2 | UL94 | |

Tip: This test data is for reference only, not as an absolute application index

Polycarbonate Film

Model | size of metric system | size of british system | Packing Standard | ||

Thickness | Width×Length mm×m | Thickness | Width×Length | ||

omay -G21

| 0.125 | 930×640.5 | 0.005″ | 3′×2100′ | Roll |

1220×640.5 | 4′×2100′ | ||||

0.175 | 930×457.5 | 0.007″ | 3′×1500′ | ||

1220×457.5 | 4′×1500′ | ||||

0.250 | 930×327.8 | 0.010″ | 3′×1075′ | ||

1220×327.8 | 4′×1075′ | ||||

0.375 | 930×228.75 | 0.015″ | 3′×750′ | ||

1220×228.75 | 4′×750′ | ||||

0.500 | 930×175.4 | 0.020″ | 3′×575′ | ||

1220×175.4 | 4′×575′ | ||||

Polycarbonate Sheet

Model | size of metric system | size of british system |

Packing Standard | ||

Thickness | Width×Length | Thickness | Width×Length | ||

0.25 | 990×711 | ||||

0.375 | 990×711 | ||||

0.5 | 990×711 | ||||

Previous: G42

Next: ST99

Copyright © 2020 苏州奥美材料科技有限公司.

All Rights Reserved.

苏公网安备32050502000950号

苏公网安备32050502000950号

苏ICP备19046638号

Address:No.158-30, Huashan Road,Suzhou SND, China

TEL : +86 512 6665 2013

+86 512 6665 2011

E-mail:omay@pc-film.com